More options for developing smart and energy-efficient materials

TSST, developer and manufacturer of deposition equipment for university research centers, has developed a vacuum transfer line. Researchers aiming to create new materials by depositing thin layers can connect various deposition devices to the transfer line. That gives them additional possibilities of developing ‘smart’ and energy-efficient materials. With this new product, TSST profiles itself as a systems integrator for deposition processes. The company has made a name with PLD (Pulsed Laser Deposition) for the research world and is now focusing on the industrial world as well. It is developing an ALD (Atomic Layer Deposition) device for this purpose that can be used in various ways, such as in the production of semi-conductors and solar cells, and that also has biomedical applications. The company has the necessary technological and financial strength because it was recently fully acquired by technology developer and producer Demcon. Today the company operates under the name Demcon TSST.

In 1998, TSST started off as a spinoff of the research group Inorganic Materials Science (IMS) and the research institute MESA+ of the University of Twente (UT) to build deposition equipment for university research centers throughout the world. The company specializes in Pulsed Laser Deposition (PLD), an advanced deposition technology. This technology is suitable for making thin layers (films) of the highest quality, but is difficult to scale up. This is why it does not lend itself well for industrialization and is therefore primarily used by researchers, who develop new, complex materials with a focus on functionality and energy efficiency. These materials, for example, are intended for ultra-efficient electronics or optics, such as micro batteries integrated into chips and other high-quality applications.

Strength

In 2015, after a long time spent pioneering at UT Campus, TSST took a step towards further professionalization by moving into Demcon’s head office in Enschede. Here, TSST became a participant in the Incubate Program in which Demcon offers starting and evolving companies design support services, accommodations, laboratory and production facilities, supplementary services and financing. Three years later, Demcon acquired a majority share in TSST and last year it became full owner. Since then TSST has become part of the Demcon group as an independent company and now operates under the name Demcon TSST. At the moment the company primarily continues to supply PLD systems and connecting modules and components. However, under Demcon’s wings, the company now has the technological and financial strength to also exploit new markets and to develop completely new products, says managing director Emiel Rutgers. ‘In this regard we continue to work together with researchers at IMS and MESA+ at UT; this partnership is very valuable for us and our clients.’

Systems integrator

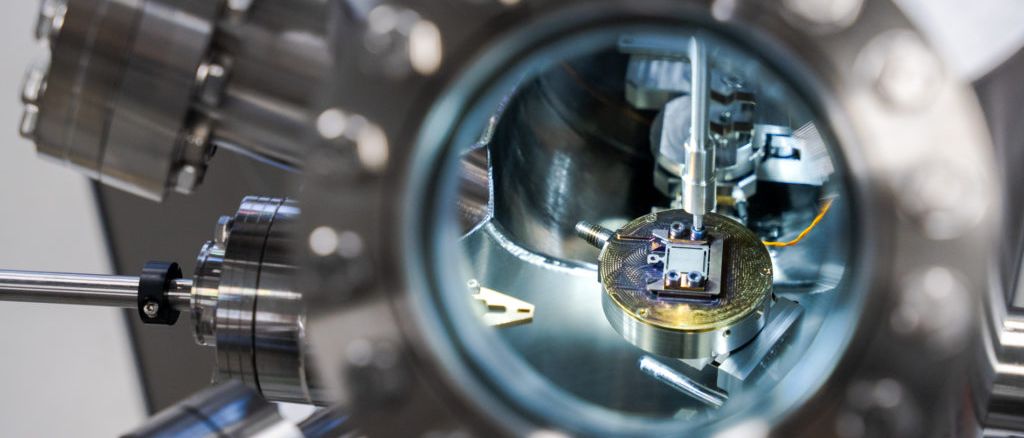

Demcon TSST recently launched a vacuum transfer line to which various deposition devices, each with its own process, can be connected. It is a transport system in which samples are transferred from one process chamber to another in a high vacuum, explains Rutgers. ‘This prevents contamination of the material and consequently prevents the sample from experiencing quality or function loss. In some cases it is essential that a sample is not exposed to atmospheric conditions. We have increasingly more clients who would like to use different deposition techniques to make complex materials with different layers, in order to be able to develop new properties. With this transfer line we are responding to that need and positioning ourselves as a deposition technology systems integrator.’In 1998, TSST started off as a spinoff of the research group Inorganic Materials Science (IMS) and the research institute MESA+ of the University of Twente (UT) to build deposition equipment for university research centers throughout the world. The company specializes in Pulsed Laser Deposition (PLD), an advanced deposition technology. This technology is suitable for making thin layers (films) of the highest quality, but is difficult to scale up. This is why it does not lend itself well for industrialization and is therefore primarily used by researchers, who develop new, complex materials with a focus on functionality and energy efficiency. These materials, for example, are intended for ultra-efficient electronics or optics, such as micro batteries integrated into chips and other high-quality applications.

Moving towards industry

Users can connect deposition processes developed by Demcon TSST and other suppliers to the new transfer line, says Rutgers. ‘Aside from PLD systems we also supply other systems, such as sputter equipment, and we are also working on developing another deposition process.’ This concerns ALD (Atomic Layer Deposition), which uses a chemical process instead of a laser, such as PLD. ALD is much more suitable for upscaling and as such for industrial production. It is already being used in industry for the production of semi-conductors, batteries and solar cells. Another interesting possibility is the use of ALD for making surfaces that are bio-compatible and that are therefore suitable for implants, for example. ‘We are currently using our deposition technology expertise to develop an ALD device. We hope to introduce it later this year so as to be able to serve new markets. It is consistent with our goal of doubling our revenue over the coming years.’

Expertise and impact

Dennis Schipper, CEO of Demcon, endorses Rutgers’ ambition. ‘Now that we fully own TSST, we are in a position to better support them in investing in new markets and technologies. With PLD they serve a niche market, while they are expanding their product range with the new transfer line and are able to cover an even larger market with ALD. This way they are aligning themselves with the expertise and ambition of the Demcon group. We are already active in the field of thin film technology, where we help researchers optimize their processes and scale up from laboratory to industrial production. Ultimately we aim to have a social impact, for example in the energy transition and biomedical market. TSST is in a position to contribute to this with PLD, and most certainly also with ALD.’